WHAT IS PROTOTYPING?

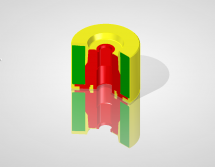

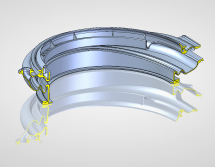

Rapid Prototyping (RP) is a technology that makes possible the execution, in just a few hours and without the help of tools, of objects of geometrically complex, directly from the mathematical model of the design made on a three-dimensional CAD system.

Italdesign is a company sensitive to technological innovations with the knowledge that businesses tend to shorten the passage between the concept phase and the exit of the product on the market. Time-to-market is significantly reduced.

Rapid prototyping meets the requirements of those companies that need fast execution of functional prototypes, accelerating the creation of a model of a part, or an assembly, through three-dimensional design (CAD).

QUOTES TO MEASURE

For a quote to measure, you may include the effective volume in cm3 of the prototype to be created in the box below, to quickly receive an approximate cost estimate.

| Volume (cm³) | Total € (VAT excluded) |

|---|---|

Honeycomb Execution

In some cases, the esthetic prototype can be made with a “honeycomb” filling, saving on execution costs.

Request an individual quote by sending an mail to info@it-design.it, attaching a design in 3D format (step, iges, parasolid) or stl format.